Engineering tomorrow’s possibilities through innovation, sustainability, and value-driven solutions.

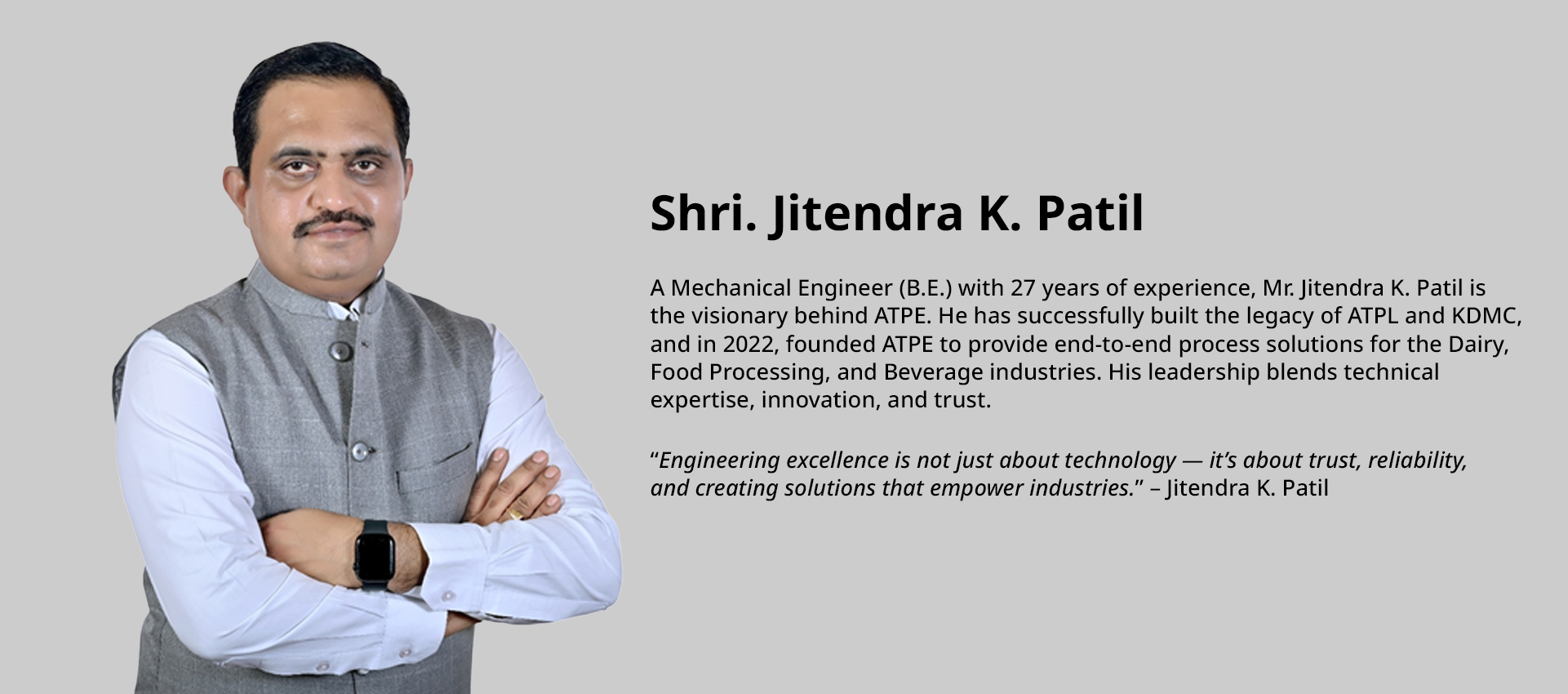

Ashtavinayaka Techno Process Engineering Pvt. Ltd. (ATPE) is a trusted leader in process plant design, fabrication, erection, and turnkey project solutions. Backed by the strong foundation of KDMC, we serve industries across dairy, food, beverage, pharmaceutical, and chemicals, delivering projects that blend engineering precision with future-ready innovation.

From concept to commissioning, ATPE provides end-to-end solutions with a focus on automation, sustainability, and global quality standards. With successful projects across India, Kenya, Azerbaijan, Bangladesh, and beyond, we are recognized as a partner who transforms visions into world-class engineering facilities.